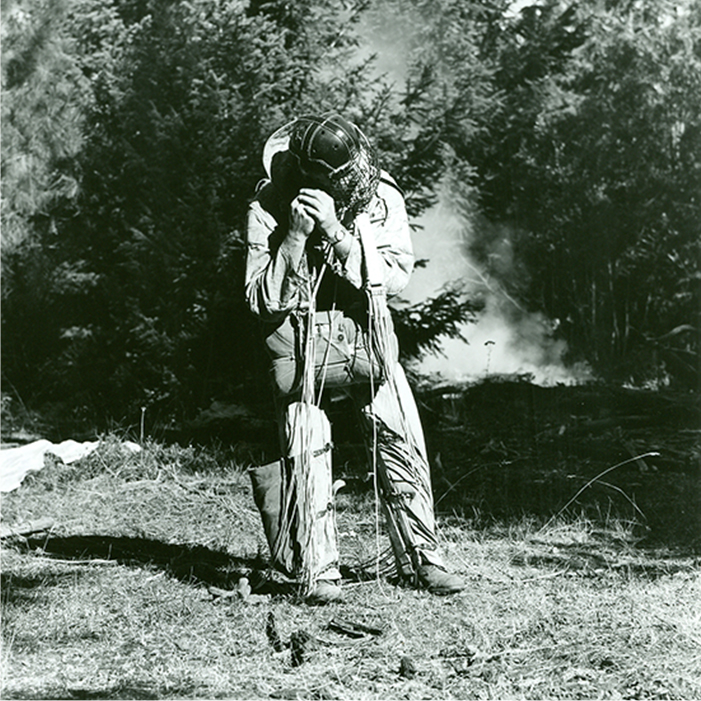

Despite the legacy of the Lineman and Logger and Packer, the longevity of White’s Boots in the 21st century comes down to one boot: the Smokejumper. In 1939, the first version of Smokejumper was worn by Francis Lufkin, an employee of the U.S. Forest Service. As a field tester and foreman for the Smokejumping program, he would become a legend in his own right. He heard about Otto White from his grandfather, who had been a log driver in St. Maries during the logging boom. In the midst of the Great Depression, Francis bought his first pair of White’s Boots for $12.00. The rest is history. No company has benefited more from word-of-mouth than White’s Boots, and the Smokejumper is the chief benefactor of it. One-by-one, smokejumpers started buying the historic 335 model.

In 1951, dealer catalogs touted the 335 as the official boot worn by smokejumpers in Region 1. The U.S. Forest Service never issued the boot as a part of their official gear, but smokejumpers bought it anyway for a week’s worth of pay. The historic Smokejumper was worn for more than 25 years. Hundreds of smokejumpers had worn it and hung it on their mantel as a trophy, but in 1963, Vibram introduced their revolutionary sole into North America and Otto’s bootmakers were there to use it.

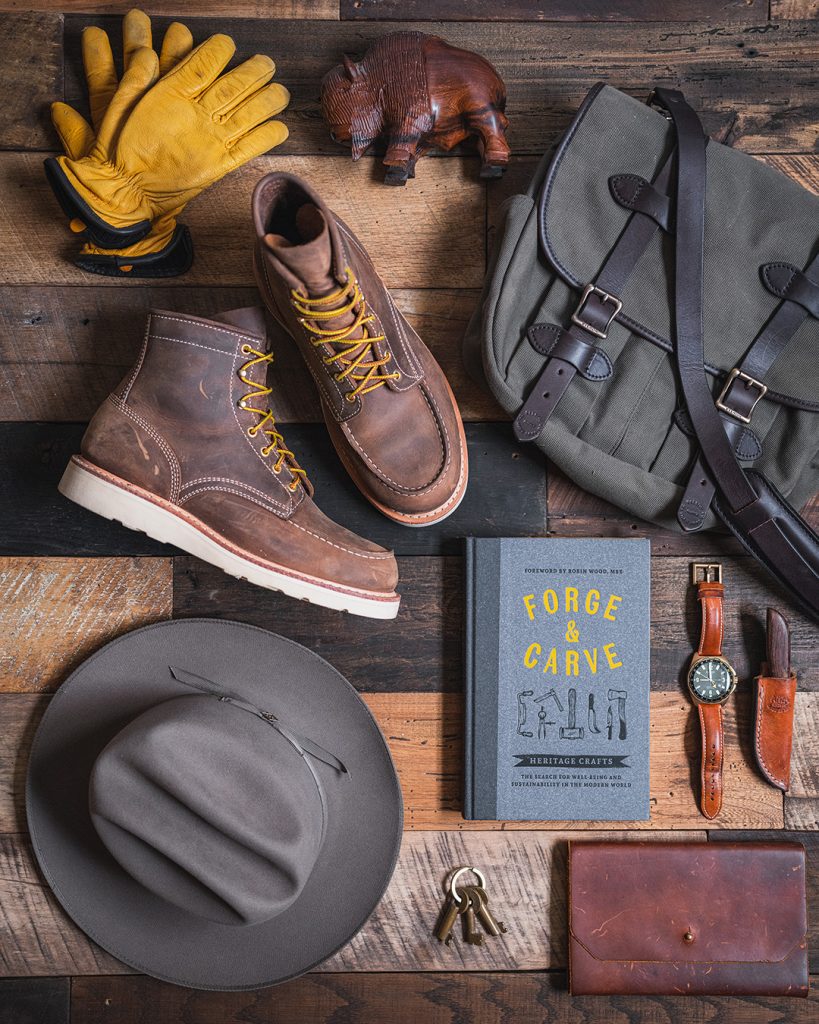

Over the next several decades, the 1963 model of the Smokejumper put White’s Boots on more than a map of the Pacific Northwest. It spread to all of North America and beyond. The Smokejumper was key to the success of the company after Otto died in 1972. By no means the only boot sold, but always the best selling, the Smokejumper is known as more than a boot for smokejumpers. They deserve the credit for wearing it and naming it, but the longevity of the Smokejumper is rooted in the 375 and 400 models Otto developed on the 4811 last in 1930. For 91 years and counting, everyone from a logger to a lineman to a farmer to a forest ranger has worn some version of it. Hand-lasted, hand-welted, and hand-bottomed, it’s a legend no matter who wears it.